Ein Faserlaserschneider ist eine hochentwickelte und effiziente Maschine, die in der Fertigungs- und Metallindustrie zum Schneiden verschiedener Materialien mit Präzision und Geschwindigkeit eingesetzt wird. Es verwendet einen Faserlaser, eine Art Festkörperlaser, der durch die Verwendung von optischen Fasern, die mit Seltenerdmetallen wie Ytterbium dotiert sind, einen hochintensiven Lichtstrahl erzeugt. Diese Technologie hat den Bereich des Laserschneidens revolutioniert und bietet zahlreiche Vorteile gegenüber herkömmlichen CO2-Laserschneidern, darunter höhere Energieeffizienz, höhere Schnittgeschwindigkeiten und die Fähigkeit, eine größere Auswahl an Materialien zu schneiden.

Wie funktioniert ein Faserlaser Cutter?

Der Betrieb eines Faserlaserschneiders beginnt mit der Erzeugung des Laserstrahls. Die Faserlaserquelle erzeugt einen Lichtstrahl, der dann durch eine Reihe von optischen Fasern auf den Schneidkopf übertragen wird. Der Schneidkopf fokussiert den Laserstrahl auf das zu schneidende Material und erzeugt einen hochkonzentrierten Energiefleck. Diese Energie erwärmt das Material bis zum Schmelz- oder Verdampfungspunkt, so dass der Laser es mit höchster Präzision durchschneiden kann.

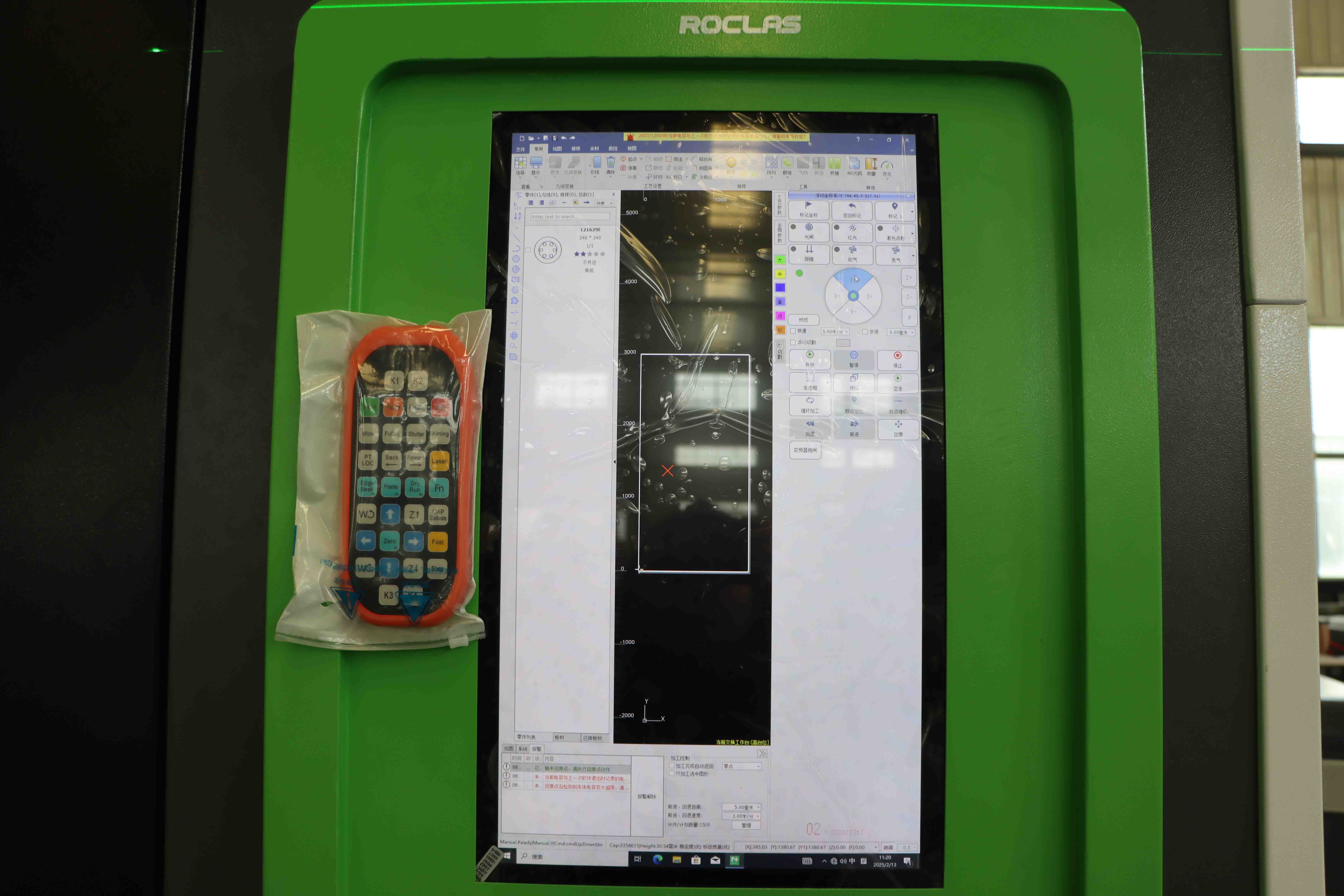

Der Schneidprozess wird durch ein computergesteuertes numerisches Steuerungssystem (CNC) gesteuert, das die Bewegung des Schneidkopfes entlang der gewünschten Bahn führt. Das CNC-System sorgt dafür, dass der Laser exakt den Konturen des Designs folgt, was zu sauberen, präzisen Schnitten führt. Der gesamte Prozess ist hochautomatisiert, wodurch der manuelle Eingriff reduziert und das Fehlerrisiko minimiert wird.

Advantages of Fibre Laser Cutters

1. High Precision and Accuracy: Fibre laser cutters are capable of producing extremely precise cuts with tight tolerances. This makes them ideal for applications that require intricate designs and high levels of detail.

2. Fast Cutting Speeds: Fibre lasers operate at much higher speeds than traditional CO2 lasers, significantly reducing the time required to complete cutting tasks. This increased speed translates to higher productivity and lower production costs.

3. Energy Efficiency: Fibre lasers are more energy-efficient than CO2 lasers, consuming less power while delivering superior performance. This not only reduces operating costs but also makes fibre laser cutters more environmentally friendly.

4. Versatility: Fibre laser cutters can cut a wide range of materials, including metals (such as steel, stainless steel, aluminum, and copper), plastics, and even some ceramics. This versatility makes them suitable for a variety of industries, from automotive and aerospace to electronics and jewelry.

5. Low Maintenance: Fibre lasers have fewer moving parts and require less maintenance compared to CO2 lasers. This reduces downtime and maintenance costs, ensuring that the machine remains operational for longer periods.

6. Compact Design: Fibre laser cutters are typically more compact than CO2 laser cutters, making them easier to integrate into existing production lines and reducing the overall footprint of the equipment.

Applications of Fibre Laser Cutters

Fibre laser cutters are used in a wide range of applications across various industries. Some of the most common applications include:

1. Metal Fabrication: Fibre laser cutters are widely used in the metal fabrication industry for cutting and shaping metal sheets and plates. They are particularly well-suited for cutting complex shapes and patterns in materials such as steel, stainless steel, and aluminum.

2. Automotive Industry: In the automotive industry, fibre laser cutters are used for cutting and shaping metal components, such as body panels, chassis parts, and engine components. The high precision and speed of fibre lasers make them ideal for producing high-quality parts with tight tolerances.

3. Aerospace Industry: The aerospace industry requires components that are both lightweight and strong. Fibre laser cutters are used to cut and shape materials such as titanium and aluminum, which are commonly used in the construction of aircraft and spacecraft.

4. Electronics Industry: Fibre laser cutters are used in the electronics industry for cutting and shaping components such as circuit boards, connectors, and enclosures. The precision of fibre lasers ensures that delicate electronic components are cut with minimal damage.

5. Jewelry Industry: In the jewelry industry, fibre laser cutters are used for cutting and engraving precious metals and gemstones. The high precision and detail offered by fibre lasers make them ideal for creating intricate designs and patterns.

6. Medical Industry: Fibre laser cutters are used in the medical industry for cutting and shaping medical devices and implants. The ability to cut with high precision and minimal heat-affected zones makes fibre lasers suitable for producing medical components that require strict quality standards.

Choosing the Right Fibre Laser Cutter

When selecting a fibre laser cutter, there are several factors to consider to ensure that the machine meets your specific needs:

1. Power Output: The power output of the fibre laser cutter determines its cutting capabilities. Higher power lasers can cut thicker and harder materials, but they also consume more energy. It is important to choose a laser with the appropriate power output for your intended applications.

2. Cutting Area: The size of the cutting area determines the maximum size of the material that can be cut. It is important to choose a machine with a cutting area that accommodates the size of the materials you will be working with.

3. Material Compatibility: Different fibre laser cutters are optimized for cutting different materials. It is important to choose a machine that is compatible with the materials you will be cutting.

4. CNC System: The CNC system controls the movement of the cutting head and ensures that the laser follows the desired cutting path. It is important to choose a machine with a reliable and user-friendly CNC system.

5. Maintenance Requirements: Fibre laser cutters require regular maintenance to ensure optimal performance. It is important to choose a machine with low maintenance requirements and easy access to replacement parts.

6. Cost: The cost of a fibre laser cutter can vary significantly depending on its specifications and features. It is important to choose a machine that offers the best value for your budget while meeting your specific needs.

Conclusion

Fibre laser cutters are a powerful and versatile tool that has transformed the field of laser cutting. With their high precision, fast cutting speeds, and energy efficiency, they offer numerous advantages over traditional CO2 laser cutters. Whether you are working in the metal fabrication, automotive, aerospace, electronics, jewelry, or medical industry, a fibre laser cutter can help you achieve high-quality results with minimal effort. By carefully considering the factors outlined above, you can choose the right fibre laser cutter for your specific needs and take your production capabilities to the next level.

Ganz gleich, ob Sie allgemeine Beratung oder spezifische Unterstützung benötigen, wir helfen Ihnen gerne weiter.