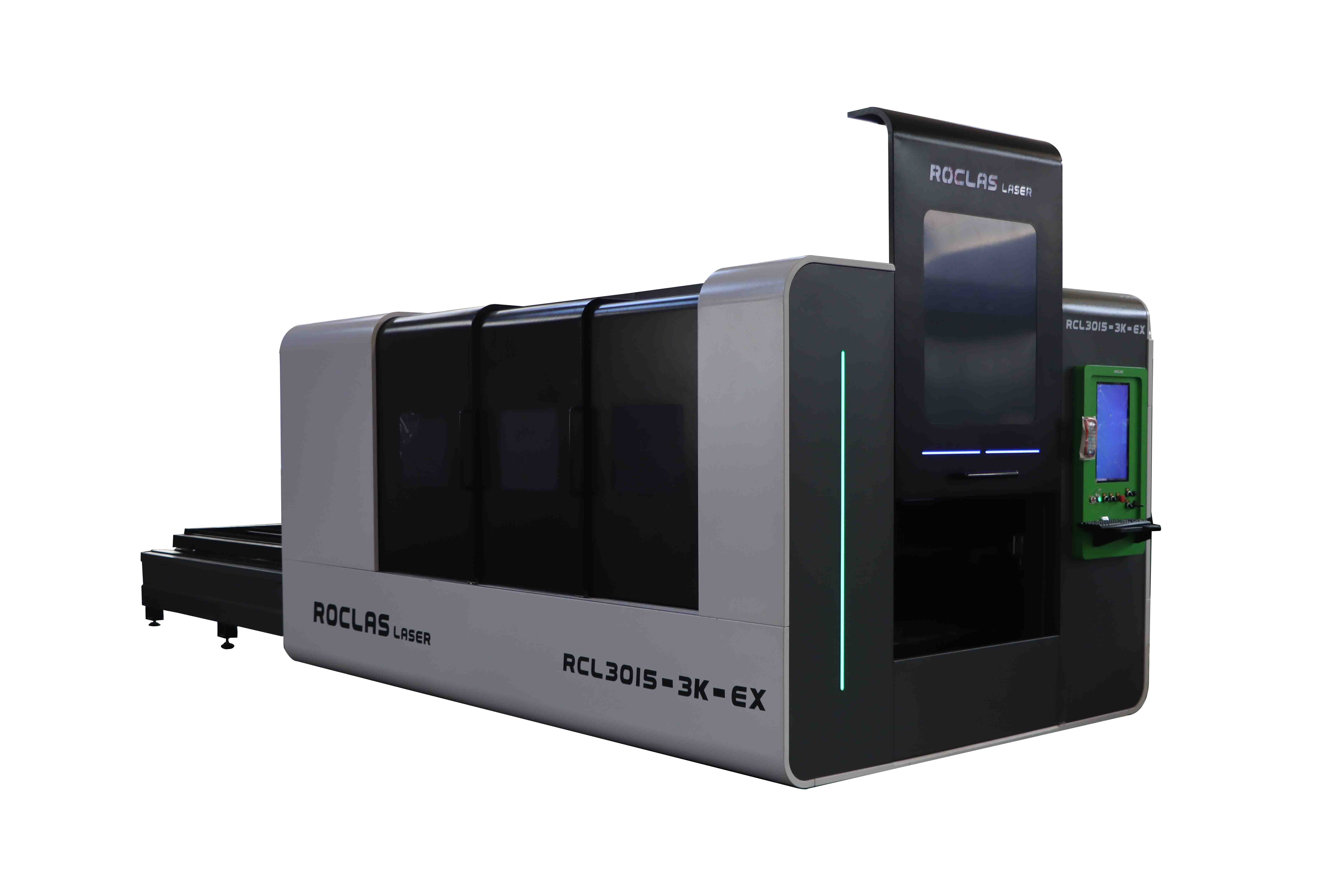

Fibre optic laser cutting machines have revolutionized the metal fabrication industry with their precision, speed, and versatility. As a leading brand in CNC laser technology, Roclas provides high-performance fibre laser cutting systems that enhance productivity while reducing operational costs. This article explores the key benefits of fibre laser cutting machines and why Roclas stands out as a top choice for manufacturers.

What Are Fibre Optic Laser Cutting Machines?

Fibre laser cutting machines utilize a solid-state laser source that generates a high-intensity beam through optical fibres. Unlike traditional CO₂ lasers, fibre lasers offer superior beam quality, energy efficiency, and minimal maintenance requirements. These machines are ideal for cutting various metals, including stainless steel, aluminum, brass, and copper, with exceptional accuracy.

Key Advantages of Fibre Laser Cutting Machines

1. Hohe Präzision und Geschwindigkeit

Fibre lasers produce a concentrated beam that allows for intricate cuts with tolerances as tight as ±0.1mm. The high cutting speed—up to 100m/min—makes them ideal for mass production without compromising quality.

2. Energieeffizienz

Fibre lasers convert 30-50% of electrical energy into laser power, compared to CO₂ lasers, which only achieve 10-15% efficiency. This reduces electricity costs significantly, making Roclas machines a cost-effective solution.

3. Niedrige Wartung & amp; Lange Lebensdauer

With no moving mirrors or gas consumables, fibre lasers require minimal maintenance. Roclas machines are built with high-quality components, ensuring a lifespan of 100,000+ hours with proper care.

4. Vielseitigkeit in der Materialverarbeitung

From thin sheets (<1mm) to thick plates (up to 30mm), fibre lasers handle a wide range of materials. Roclas systems support automated loading/unloading, making them perfect for industries like automotive, aerospace, and electronics.

5. Reduced Operating Costs

No gas consumption (unlike CO₂ lasers) and lower power requirements lead to 30-50% cost savings over time. Roclas machines also feature smart software for optimized material usage, reducing waste.

Why Choose Roclas Fibre Laser Cutting Machines?

Roclas ist ein vertrauenswürdiger Name in der Laserschneidtechnologie, bietet

- Advanced CNC controls for seamless operation

- High-power laser sources (1kW-30kW) for industrial-grade cutting

- User-friendly interfaces for easy programming

- Reliable after-sales support and maintenance services

Schlussfolgerung

Fibre optic laser cutting machines are the future of metal fabrication, delivering unmatched precision, efficiency, and cost savings. Roclas provides cutting-edge solutions tailored to modern manufacturing needs. Whether for small workshops or large-scale production, investing in a Roclas fibre laser cutter ensures higher productivity and superior quality.

For more details, visit Roclas’ official website and explore our range of high-performance laser cutting systems!

Ganz gleich, ob Sie allgemeine Beratung oder spezifische Unterstützung benötigen, wir helfen Ihnen gerne weiter.