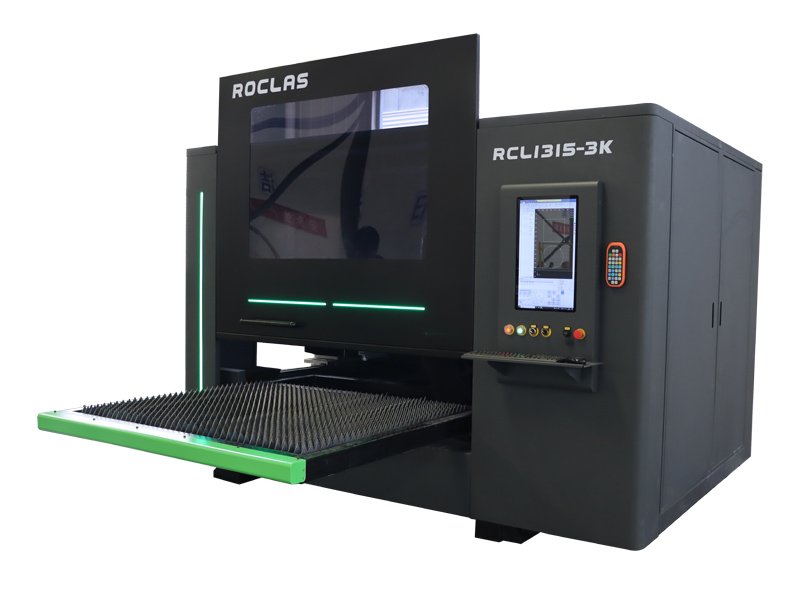

The processing accuracy of a laser cutting machine is a critical factor that determines its performance. ROCLAS has successfully achieved an impressive 0.01mm processing accuracy, setting a high standard in the industry. Let's take a closer look at the key technologies that make this precision possible.

At the heart of ROCLAS' accuracy lies its high-precision mechanical structure. The machine adopts a high-strength steel tube structure that undergoes tempering and stress-relief processes. This treatment ensures maximum bed strength, maintaining stability even during high-speed operation and effectively minimizing vibrations that could compromise accuracy.

The machine's motion system is equipped with imported high-precision linear guides and ball screws. These components feature a low friction coefficient, enabling smooth operation with minimal wear over time. This combination guarantees the machine's accuracy is maintained during rapid movements, which is essential for achieving the 0.01mm tolerance.

ROCLAS' control system plays an equally important role in maintaining precision. The advanced digital control algorithms constantly monitor and adjust the cutting parameters in real-time, compensating for any potential deviations. This closed-loop control system ensures consistent accuracy throughout the cutting process.

The optical system is another crucial element. ROCLAS uses premium-quality focusing lenses that maintain a consistent focal point, ensuring the laser beam remains precisely focused on the material surface. This optical precision directly contributes to the overall accuracy of the cuts.

Temperature control mechanisms are integrated into the system to counteract thermal expansion effects that could otherwise affect accuracy. The machine maintains a stable operating environment, preventing heat-related distortions that might impact the precision of the cuts.

Regular maintenance and calibration procedures are part of ROCLAS' commitment to sustained accuracy. Technicians perform routine checks and adjustments to ensure all components remain within their optimal operational parameters. This preventive approach helps maintain the 0.01mm accuracy over the machine's lifetime.

For customers who require further clarification or detailed technical specifications, ROCLAS' support team is always available to provide comprehensive information and customized solutions tailored to specific application needs. This customer-focused approach ensures users can fully leverage the machine's precision capabilities in their operations.

Vorherige:Roclas Fiber Laser Cutting Machine Could Help You Find the Perfect Laser Cutting Solution

Weiter:Nicht

Ganz gleich, ob Sie allgemeine Beratung oder spezifische Unterstützung benötigen, wir helfen Ihnen gerne weiter.