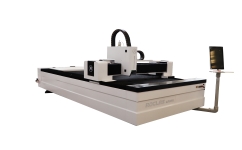

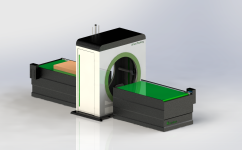

Roclas Metal Sheet and Tube Fiber Laser Cutting Machine

In today's fast-paced industrial world, precision and efficiency are key to staying competitive. The Roclas Metal Sheet and Tube Fiber laser cutting machine is a standout solution for manufacturers who demand high accuracy and versatility. With its robust design and advanced features, this machine is designed to handle a wide range of materials and thicknesses, making it a valuable asset for metal fabrication shops, automotive suppliers, and aerospace component manufacturers.

One of the most impressive aspects of the Roclas machine is its power options. Available in configurations ranging from 1000W to 8000W, it can effortlessly cut through thick metals or delicately engrave intricate patterns. The laser source, provided by Raycus or MAXLaser, ensures consistent performance and long-term reliability. Whether you're working with stainless steel, aluminum, or carbon steel, this machine adapts to your needs without compromising on quality.

The working area of 3000x1500mm provides ample space for large sheets or multiple smaller parts, maximizing productivity. The X/Y axis position accuracy of ±0.03mm and reposition accuracy of ±0.02mm guarantee that every cut is precise, minimizing material waste and reducing the need for manual adjustments. This level of accuracy is particularly important for industries where tight tolerances are non-negotiable.

The machine's control system, Cypcut 3000S, is user-friendly yet powerful. It supports a variety of file formats and allows for complex designs to be programmed with ease. Operators can quickly switch between different tasks, saving time and reducing downtime. The interface is intuitive, so even those with limited experience can learn to operate the machine efficiently.

Durability is another strong point of the Roclas laser cutter. Built to withstand the demands of heavy industrial use, its components are designed for longevity. Regular maintenance is straightforward, ensuring that the machine remains in peak condition with minimal interruptions. This reliability translates to lower operational costs over time, making it a smart investment for businesses.

Safety features are also a priority. The machine includes protective shields and sensors to prevent accidents during operation. Additionally, the laser cutting process produces minimal heat-affected zones, reducing the risk of material warping and preserving the structural integrity of the finished product.

In summary, the Roclas Metal Sheet and Tube Fiber Laser Cutting Machine combines power, precision, and ease of use in a single package. Its adaptability to different materials and thicknesses, coupled with its impressive accuracy, makes it a top choice for modern metalworking. Whether you're a small workshop or a large-scale production facility, this machine delivers consistent results, helping you meet deadlines and maintain high standards. As technology continues to evolve, the Roclas laser cutter remains a reliable tool for those who value quality and efficiency in their manufacturing processes.

Get a Quote

Regardless of whether you require general advice or specific support, we are happy to help you.