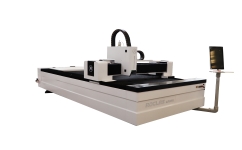

Roclas Laser Welding Machine: Precision Engineering for Modern Manufacturing

In the rapidly evolving industrial landscape, Laser welding technology has emerged as a cornerstone of precision manufacturing. Among the leading innovators in this field, Roclas stands out with its advanced Laser welding machines, designed to meet the diverse needs of industries ranging from automotive to aerospace. This essay explores the key features of Roclas's laser welding technology, focusing on its power options, multifunctionality, laser head design, laser source, water chiller system, and wire feeder functionality.

1. Optional Power: Flexibility for Diverse Applications

Roclas's laser welding machines are available in four power options: 1000W, 1500W, 2000W, and 3000W. This flexibility allows manufacturers to select the machine that best suits their specific welding requirements. The 1000W model is ideal for delicate tasks, such as welding thin sheets of metal, while the 3000W model is designed for heavy-duty applications, including welding thick materials or high-strength alloys. By offering a range of power options, Roclas ensures that its machines can be used across a wide spectrum of industries, from jewelry making to automotive manufacturing.

2. Multifunctionality: A Versatile Solution for Multiple Processes

One of the standout features of Roclas's laser welding machines is their multifunctionality. These machines are not limited to welding alone; they can also perform cleaning, cutting, and weld seam cleaning tasks. This versatility is achieved through a four-mode system that allows users to easily switch between welding, cutting, cleaning, and weld seam cleaning modes. For instance, in the automotive industry, a single machine can be used to weld components, cut excess material, and clean the weld seams, streamlining the production process and reducing the need for multiple machines.

3. Laser Head: Precision Engineering for Optimal Performance

The laser head is a critical component of Roclas's welding machines, designed to ensure precise and efficient laser delivery. The process begins with the laser source generating a high-intensity beam, which is then transported to the welding head. Here, the beam is collected and reflected by a reflector and focused by the focusing lenses before being directed through the nozzles and fired onto the materials. This sophisticated design ensures that the laser beam is concentrated and controlled, resulting in high-quality welds with minimal heat-affected zones. The laser head's precision is particularly beneficial for welding intricate components, such as electronic parts or medical devices, where accuracy is paramount.

4. Laser Source: Compact Design for Enhanced Portability

Roclas's laser source is a professional-grade component that is small in size, light in weight, and easy to move. This compact design makes the machine ideal for applications where space is limited or where portability is required. The light emitting mode of the laser source is optimized to achieve a good welding effect, ensuring consistent and reliable performance. Additionally, the laser source supports power options ranging from 1KW to 3KW, providing users with the flexibility to choose the power level that best suits their welding needs. Whether working in a factory or on-site, Roclas's laser source offers the versatility and reliability required for modern manufacturing.

5. Water Chiller System: Temperature Control for Consistent Performance

To maintain optimal performance, Roclas's laser welding machines are equipped with a water chiller system. This system uses pure water in summer to prevent overheating and ensure efficient cooling. When the room temperature drops below 5 degrees Celsius, the system switches to using antifreeze in the water to prevent freezing and maintain consistent performance. As the temperature warms, the system automatically switches back to pure water. This intelligent temperature control mechanism ensures that the machine operates efficiently year-round, regardless of external conditions. The water chiller system is particularly beneficial in regions with extreme temperature variations, where maintaining consistent performance is critical.

6. Wire Feeder: Standard Automatic Feeding for Seamless Operation

Roclas's laser welding machines come equipped with a standard automatic wire feeding system. This system ensures a continuous and consistent supply of welding wire, reducing the need for manual intervention and minimizing downtime. The automatic wire feeder is designed to work seamlessly with the laser welding process, ensuring that the wire is fed at the optimal rate for high-quality welds. This feature is particularly useful in high-volume production environments, where efficiency and reliability are key. By automating the wire feeding process, Roclas's machines help manufacturers increase productivity and reduce operational costs.

Roclas's laser welding machines represent a leap forward in precision manufacturing technology. With their optional power options, multifunctionality, advanced laser head design, compact laser source, intelligent water chiller system, and standard automatic wire feeder, these machines offer unparalleled versatility and performance. Whether used in automotive, aerospace, or other industries, Roclas's laser welding machines are designed to meet the highest standards of quality and efficiency. As industries continue to evolve, Roclas's commitment to innovation ensures that its machines will remain at the forefront of laser welding technology, driving progress and enabling manufacturers to achieve new levels of precision and productivity.

Get a Quote

Regardless of whether you require general advice or specific support, we are happy to help you.